For over 40 years, Stainless Engineering Co. Ltd has specialised in the fabrication of high quality stainless steel tanks and industrial equipment from stainless steel, in thicknesses from 1.5mm up to heavy plate. While many companies have moved manufacturing overseas to save costs, at Stainless Engineering we believe that our success in a competitive industry is due to staying local to ensure swift response, and placing an emphasis on providing exemplary service and quality.

The fabrication plant has always been based in East Tamaki and in its current location since the early 1980’s, and many clients have been with the company since the early days. The loyal company culture means that many of the team have been with Stainless Engineering for many years, and others have returned to the company after working elsewhere. Our highly skilled team of engineers and fabricators offer extensive experience in fabrication, design and development, project management and process engineering.

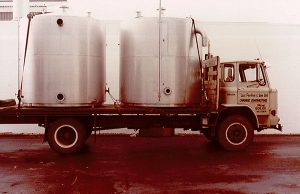

Stainless Engineering was started 40 years ago by Director Leanne Morris’s father, Geoff Morris, and his business partner Wayne Lye. One of the company’s original areas of expertise was producing stainless steel fabricated tanks and other products for the wine industry, which was a major growth sector in the 1970s. The business focus has expanded to fabrication of stainless steel products for a wide range of industries, including food, beverage, dairying, chemical processing, and pharmaceuticals.

The company’s core business remains industrial processing equipment, pressure vessels, stainless steel storage and mixing tanks, kettles, blenders, platforms, condensers, strainers, augers, pipework and ducting, in stainless steel from 1.5mm up to heavy plate.

Stainless Engineering continues to look to the future and invest in technology, people and equipment. The business has obtained ISO 9001 Certification.

We look forward to talking to you about your stainless steel fabrication needs. Please make contact today.